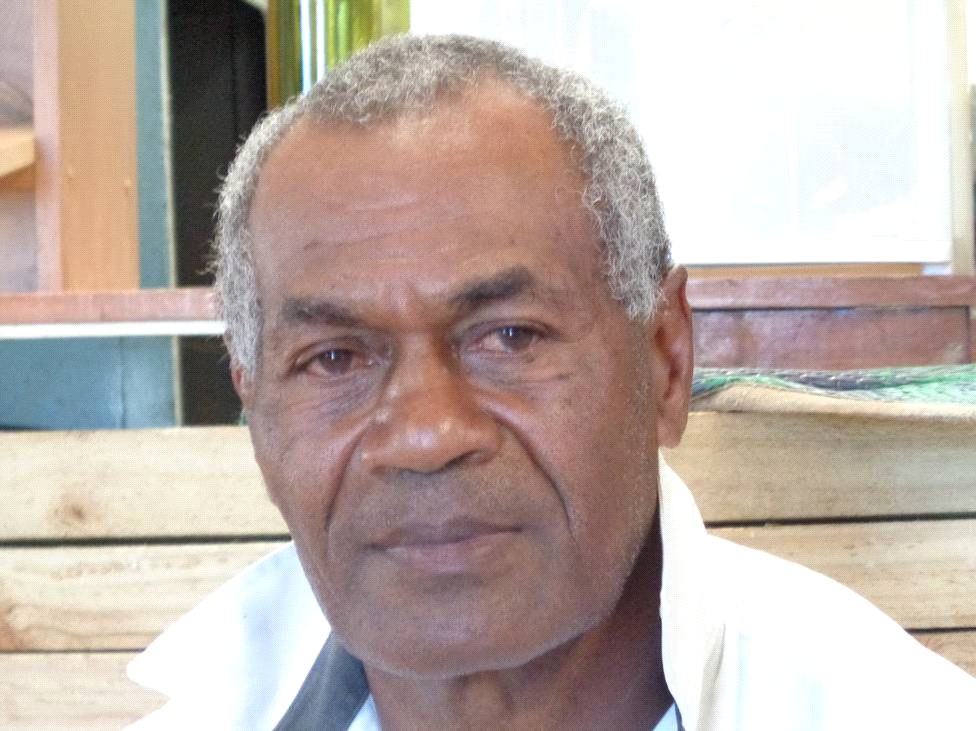

During 2016 and 2017, Daniel Shafer – Director of Nikua Training Center, served as lead technical advisor on biofuel development and energy policy for pacific island countries on behalf of the Global Green Growth Institute, which is a multinational aid agency based in Seoul S. Korea.

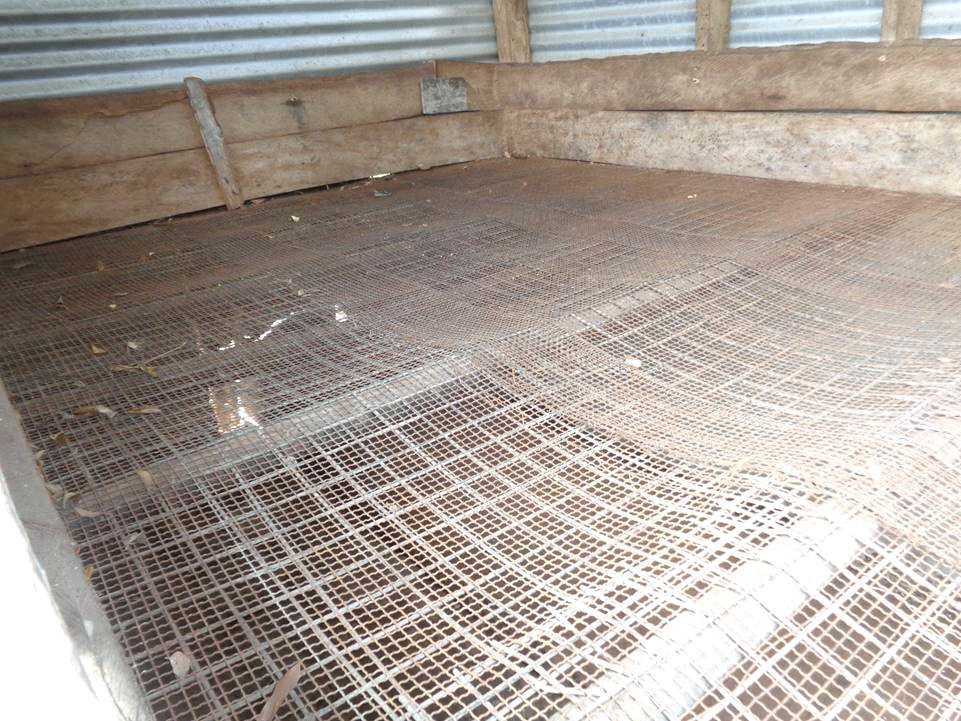

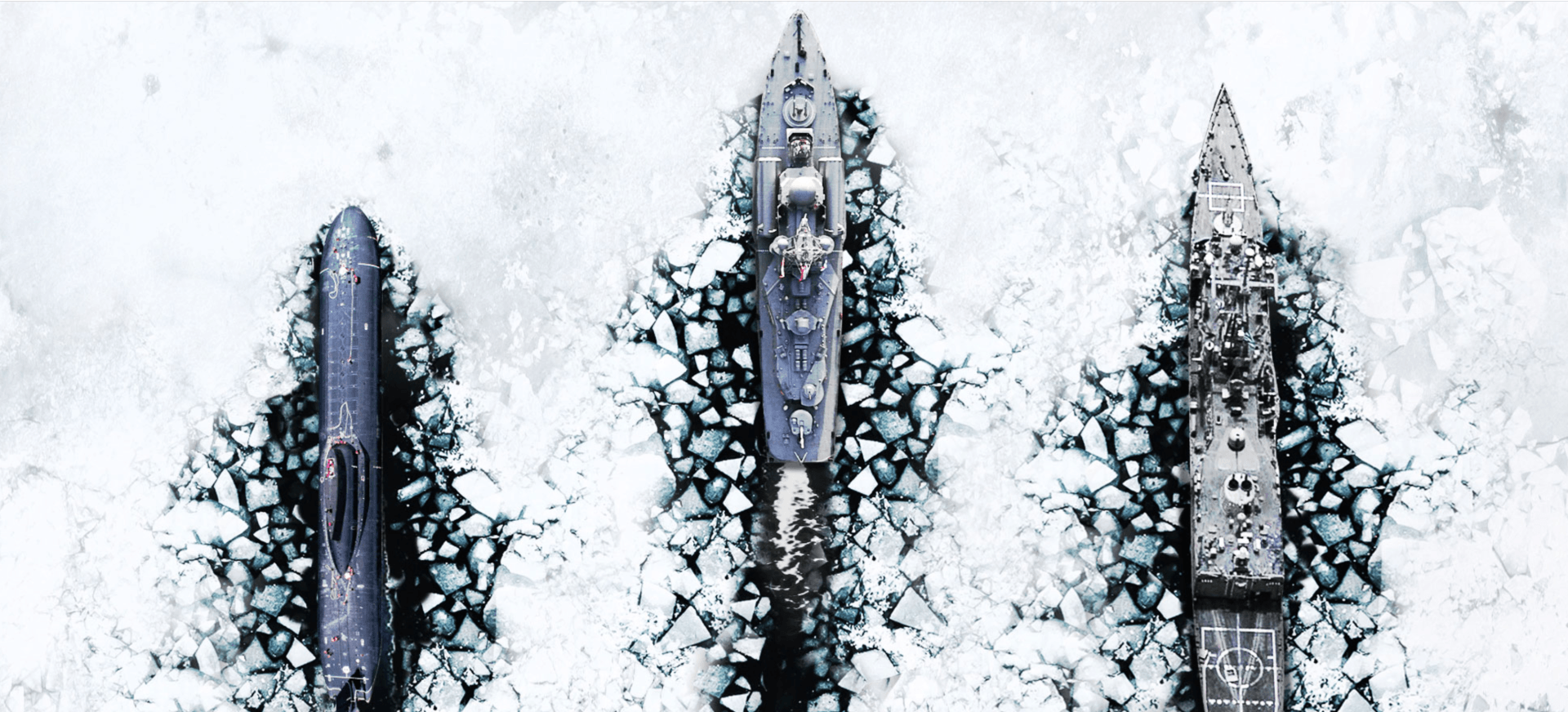

On this project I led a team of 11 financial auditors and mechanical engineers from the Department of Energy to develop business plans for the Rural Biofuel Mills in support of the National Biodiesel Plan. We led a workshop for the Ministry of Infrastructure and Transport, the Ministry of Economy, and the Fiji Department of Energy. The project included a 1,500 mile trip on an ocean going ship, traveling to all eight of the remote islands in Fiji where the government has constructed biofuel plants. The rural biofuel mills are similar in design to the pilot plant which we built in 2012. A national reorganizational plan is underway for the biofuel mills including technical upgrading to produce international quality standard biodiesel and advanced Hydrotreated Vegetable Oil – HVO Marine Diesel.

Energy is the foundation for economic development. In the South Pacific, people get almost all of their electricity from diesel-electric generators. They have the most expensive electricity rates in the world, as much as $2 USD for 1 kwh whereas in the USA the cost is below $0.20 per kwh. People suffer from “energy poverty” as the United Nations describes it. They are stuck without the ability to develop economically until energy supply becomes reliable and affordable. Rural islands in the South Pacific are at the end of an unreliable distribution chain, often causing villages to run out of fuel for one week out of every month.

The revised mill site business plan includes earning export revenue on production of premium quality virgin coconut oil, production of copra oil for biofuel and copra meal for use as animal feed. Copra contains 70% coconut oil, which is the nicest vegetable oil for production of biodiesel, HVO fuel, and for straight vegetable oil – SVO biofuel. Domestic production of biofuels allow for import substitution, offsetting spending valuable international currency earnings and allowing for substitution of costly imported petroleum.

Presently the mills don’t earn export revenue on copra meal because the mill sites are so remote. With the Ministry of Agriculture we are developing a business model where the mill sites retain the coconut meal and become vertically integrated to manufacture animal food products like chickens and pigs. Biodiesel can be used at 100% concentration in diesel engines for electric generation and for water pumping. Nikua’s plan to install hardware for production of biodiesel and HVO fuel, will promote grid extension, rural power generation stations, and village mini-grids for power distribution.

People living on rural islands in the South Pacific want jobs. Here $100 USD a week is considered a good wage, yet people pay twice what Americans pay for everything. For one dozen eggs the cost is about $3.00 if they can get it. When I finish my work, the people in these beautiful and isolated communities will have more food and more energy at lower prices and more jobs. The Fijian people are really kind and appreciate my work here. Their Christian faith is important to the community.

Enjoy the photos from my 35 day mission to the remote islands of Cicia, Lakeba, Rabi, Koro, Gau and Rotuma.